Professional

Microsoft

I'm working as a data and applied scientist for Microsoft focused on applying the latest developments in machine learning to improve Bing's image results.

I also regularly attend the [Advanced] Data Science Reading Groups put on by Learn Data Science which are now being held virtually. I'm always interested in discussing machine learning; feel free to reach out if you want to work together on a project.

University of British Columbia

I hold a Ph.D. in Materials Engineering from the University of British Columbia which I completed at the end of 2018 while working under the supervision of Professor Anoush Poursartip.

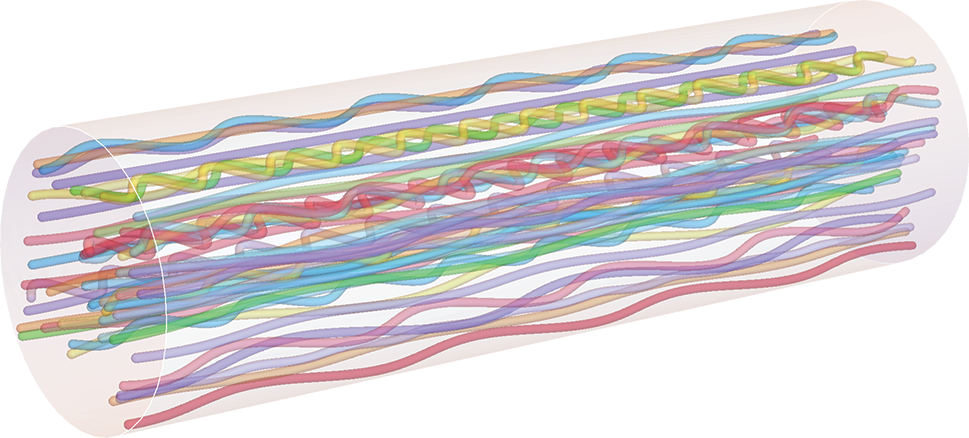

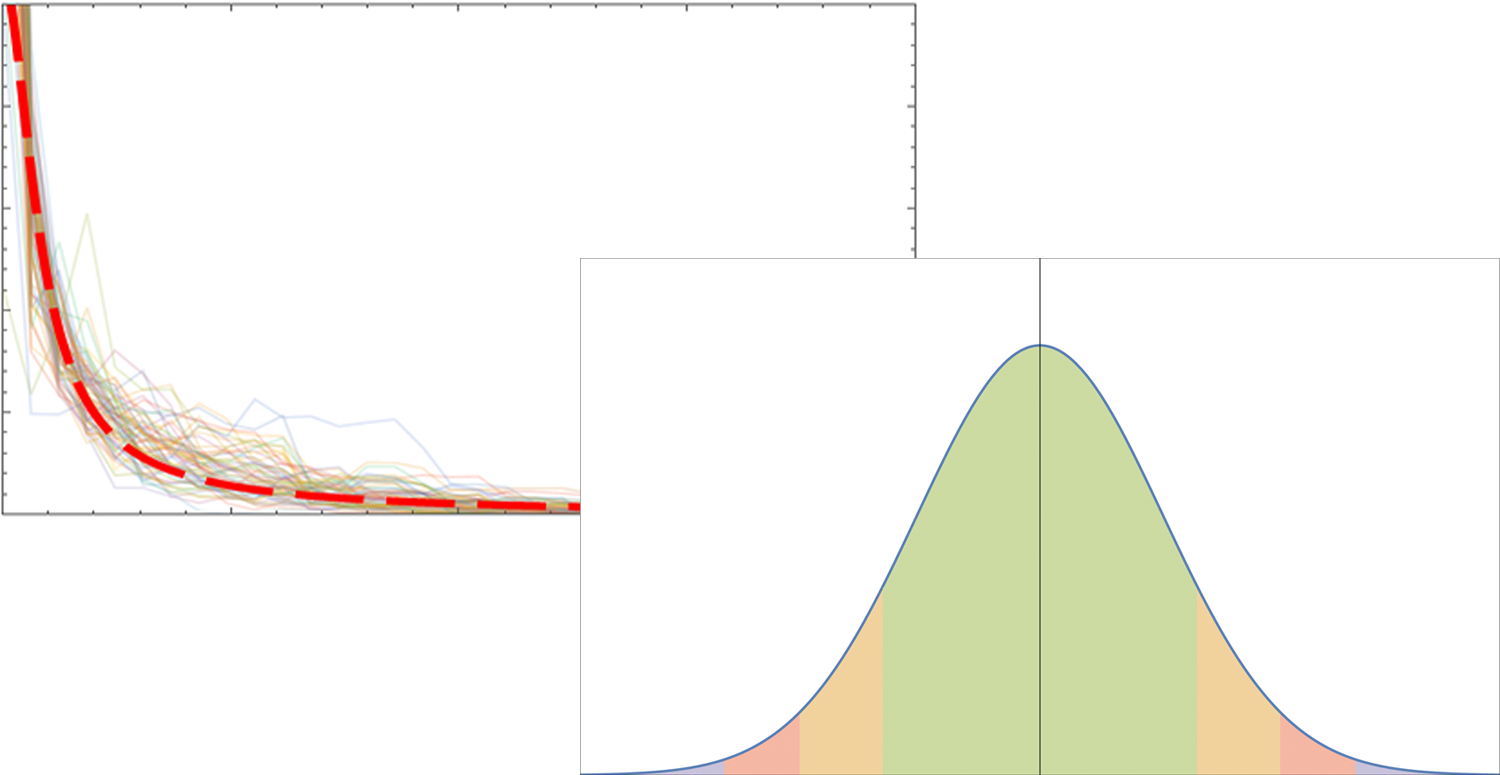

The focus of my research was in the area of fibre alignment defects occurring during processing of aerospace grade carbon fibre reinforced composite materials. Much of my work employed image analysis techniques to generate large datasets on incoming material properties as well as applying image analysis to track defect initiation and propagation. Working with these large datasets necessitated the creation of novel automated techniques to effectively reduce the information into communicable results.

University of Ottawa

I completed my master's of applied science at the University of Ottawa under the supervision of Professor François Robitaille in the summer of 2012. My area of research was in the measurement and analysis of fluid transport through porous media, specifically with respect to liquid transport moulding of composite materials. The title of my thesis was 'Measurement and Analysis of Flow in 3D Preforms for Aerospace Composites'; a digital copy of it can be found here.

I graduated cum laude from the University of Ottawa in the spring of 2010 where I received a Bachelor of Applied Science in Mechanical Engineering.

PhD Research

Data driven contributions

My doctoral work focused on carbon fibre reinforced polymer (CFRP) materials. Specifically, I studied a type of fibre alignment defect, wrinkling and waviness, observed during manufacturing.

From the Boeing 787 Dreamliner to the BMW i3, CFRP parts have on the order of millions to billions of individual carbon fibres. However, typical datasets in this field are composed of tens to hundreds of data points. As part of my work, I created an automated procedure, based on image recognition and manipulations techniques, which was able to quickly and effectively return information on over 200'000 fibres. Using this information, along with other novel approaches, I was able to provide a phenomenological model for underlying fibre architecture. The high statistical power from the large dataset provided very high confidence in the results and has been published in the peer reviewed Composites Part A journal.

Stereo reconstruction

I'm currently working on a project to create moving, depth aware, videos a-la Harry Potter portraits or a rudimentary implementation of Google's Project Starline. I'm using a Raspberry Pi 4 + Arducam setup to get the stereo images then processing the stereo images using classical methods and machine learning approaches to create the depth maps. Ultimately, I hope to display them on a glasses free 3D display like my Looking Glass Portrait.

LED Wall

This is my latest, finished, project. I designed and built this piece after being inspired from the movie Ex Machina. You can find a full build log here and all of the (free and open source) files here. The finished piece is a little over 6 feet wide by 3 feet tall with just shy of 1200 RBG LEDs all controlled by a Raspberry Pi 3B+.

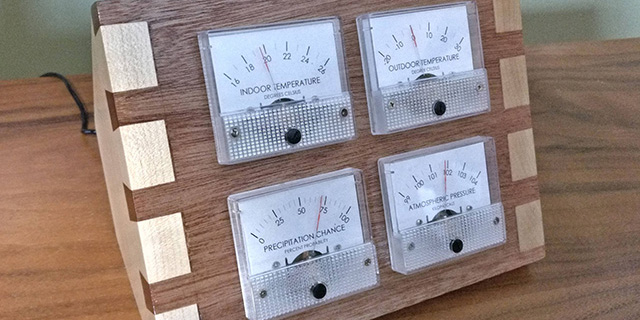

Weather station

This weather station was one of the 'shorter' build projects that I designed and made. The build log is available here. It uses Particle Photon as a microcontroller with WiFi to fetch the outdoor weather conditions using Dark Sky's API coupled with a regular NTC thermistor to measure the indoor temperature. These are then displayed on some analog amp meters fit with the appropriate readouts.

Automated blinds

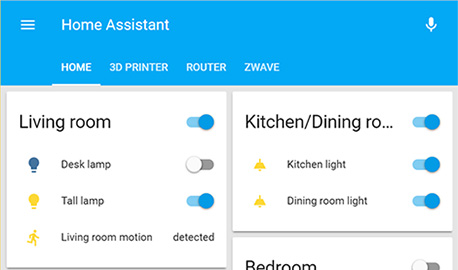

Another one of the combined software, microcontroller, and hardware projects that turned out great is this automated blinds project. The build log is available here. It uses an ESP8266 microcontroller to listen for an MQTT command. With the right command, it would rotate a servo attached to a gear train ultimately opening or closing our blinds. The MQTT client was connected to a Home Assistant MQTT broker which allowed me to use voice commands from either Amazon's Alexa or our Google Home to remotely control the blinds.

Settlers of Catan

This is a Settlers of Catan board that I printed and painted. The build log is available here. It uses these amazing designs courtesy of JAWong and Dakanzla. Took about 2 kg of PLA to print and about 3-4 coats of paint on each tile.

About

About me

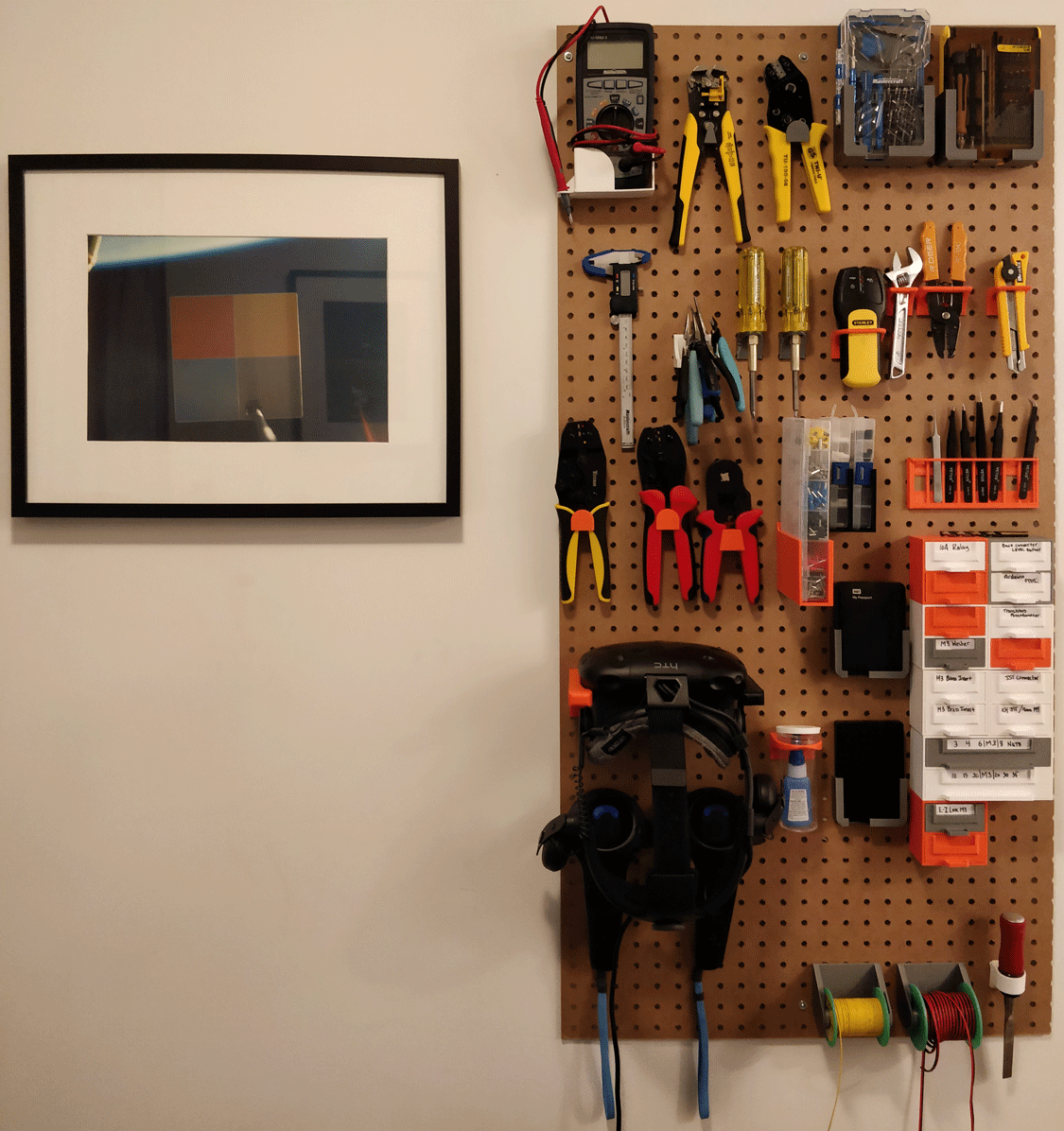

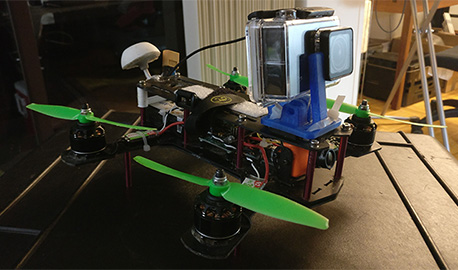

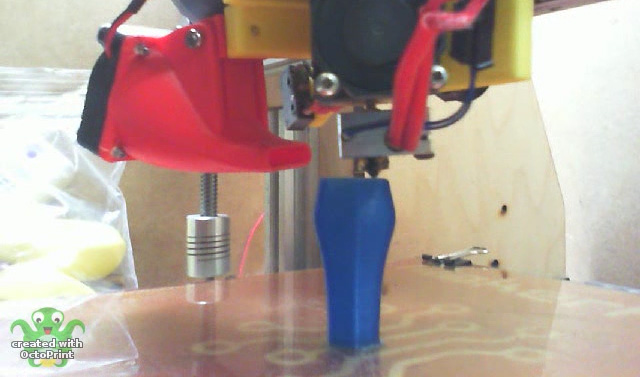

I'm the type of person who really enjoys learning in general; so when I'm not focusing on doing MOOCs or work, I typically have one (or a few) projects on the run. I'm mainly interested in DIY projects, especially the intersection of electronics and mechanics. I built a 3D printer a few years ago and it is an instrumental part in realizing most of my projects; from fitting GoPro's onto drones to servo housings for automating my blinds.

I've just finished building the LED wall inspired from the movie Ex Machina. I'm currently working on machine vision project for automating security; I also have ideas on building a robotic chess board based off of a Core-XY gantry design and standard 2020 extruded aluminium.

From the Raspberry Pi3 running an nginx server forwarding you this page right now to my 20+ piece collection of Rubik's cubes, if you have any questions or want to collaborate on a project, please feel free to e-mail me.

Contact

- Personal: [email protected]

Professional: [email protected] - Resources

- Github

- Phone

- (604) 440-4268

- Address

- Currently somewhere in Ottawa, Ontario

Canada